Sep 2008 Newsletter - Transmissions Vol 2, 2008

GRI Newsletter

As surely as the leaves changing color, a sign of summer coming to an end on a University campus is the returning students. As I write this preamble, a deserted campus and an equally deserted college town is returning to life. However, we have been busy this summer. The Board of Trustees met on August 4 to review the activities and the status of Gear Research Institute and to conduct its Annual Meeting. Attending for the first time and representing the AGMA was Robert Wasilewski, Manager Design Engineering at Arrow Gear. He replaced William Bradley who retired from the Board this year.

Over the summer we hosted a summer intern in our laboratory, who has since returned to his educational institution as a senior pursuing his undergraduate degree in Material Science. One of the highlights of the Board meeting was presentations by the graduate student and the undergraduate intern, supported by the Institute’s student support grant, on their research activities. The Board also generously extended the student support grant so that we will recruit one or more students to work in the Institute in the 2008-2009 time frame.

I am glad to say that, in spite of all the “doom and gloom” in the economy the Institute is healthy with a considerable amount of sponsored activity. Included in this is our first ever sponsored project from a German wind energy company. We have several meetings planned for the Fall and the Winter. The Steering Committee of the Aerospace Bloc will probably meet in the Fall and the Board will convene sometime early next year. These dates will be announced on the www.gearresearch.org web site when they are finalized.

Suren Rao

Managing Director

Research Projects

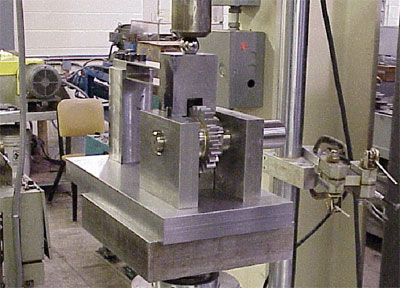

With the dramatic growth of the wind energy sector and the significant challenges faced by this sector regarding the reliability and durability of transmissions, we are gratified to be a part of the solution. We initiated our first ever project sponsored by a German manufacturer of wind turbine gear boxes. The project is currently focused on evaluating the bending fatigue strength of test gears fabricated from a variety of gear steels commercially available in Europe and the United States. A standard test gear was defined in cooperation with the sponsor and a bending fatigue test fixture, similar to the one pictured in figure 1, was designed and fabricated to hold the test gear.

Figure 1. Tooth Bending Fatigue Test Fixture

This fixture will be mounted on one of our universal test machines and the bending fatigue properties of the gears will be characterized. It is anticipated that once the superior alloys are identified, other characteristics such as surface fatigue and scoring resistance will be evaluated in future projects.

We were also contracted by a manufacturer of coatings to evaluate their surface treatment in gear applications. In fact evaluation of hard, thin film coatings for gears is a very active area of investigations. Discovering a coating that would significantly increase the surface durability of gear teeth would be a major enhancement in gear technology. It remains elusive.

Figure 2: RFC Test Machine

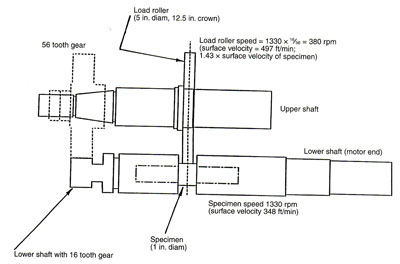

One of the least expensive ways to evaluate coatings is the rotating/sliding contact fatigue (RCF) test. In this test a cylindrical test specimen, coated or uncoated, is run under contact stress against a load roller. The two are engaged through gears to provide sliding and rolling at the contact interface and simulates the conditions of the gear tooth mesh. Figure 2 is an illustration of the TCF text machine and a schematic of this test is illustrated in Figure 3:

Figure 3. RFC Schematic

Other sponsored projects, involving investigations of gear related strength and durability of carburizing grade stainless steels, characterization of fatigue properties of AMS 6308 steel at elevated temperatures, fatigue properties of P/M alloys and studying the behavior of AMS 6308 failures in “high cycle”, bending fatigue, continue.

Education and Training

The Gear Research Institute will continue to provide student support for the school year 2008-2009, which was approved by the Board. Last years student support paid 2 semesters of tuition and half-time summer support for a graduate student (MS) in addition to full-time support for an undergraduate summer intern. Exposing good engineering students to gear technologies and providing hands on gear related training is another way that the Gear Research Institute supports the gear industry.

Because of our relationship with the AGMA the Gear Research Institute is exploring ways to better serve the AGMA membership such as through improved communication. There will be more to say on this topic as plans are developed.

The Gear Research Institute is a non profit corporation. It has contracted with the Applied Research Laboratory of The Pennsylvania State University to conduct its activities, as a sponsor within the Drivetrain Technology Center. The Gear Research Institute is equipped with extensive research capabilities. These include rolling contact fatigue (RCF) testers for low- and high-temperature roller testing, power circulating (PC) gear testers for parallel axis gears with a 4-inch center distance (testers can be modified to accommodate other center distances), single tooth fatigue (STF) testers for spur and helical gears, gear tooth impact tester, and worm gear testers with 1.75 and 4-inch center distances. Extensive metallurgical characterization facilities are also available at Penn State in support of the Gear Research Institute. For further details on our testing capabilities please go to the Drivetrain Technology Center website or call Dr. Suren Rao, Managing Director, at (814) 865-3537.