Jun 2018 Newsletter - Transmissions Vol 21, 2018

Vol. 21, 2018

Vol. 21, 2018

Foreward

This newsletter highlights the work being done in the GRI Aerospace Bloc today. This group has been in existence for 30 years now and is still going strong. I was involved in the early years when Dale Breen and Don Borden were working to provide a means for U.S. companies to conduct gear research without creating their own laboratories. They came up with the idea of pre-competitive research where projects could be conducted at reduced cost due to group funding and sharing of results. It was a time when gear research was not being funded in the U.S. but was supported substantially by governments in Germany and Japan. It was a means to work on topics important to the whole aerospace community where no one company could do the work alone.

The gear research environment has changed since that time but the concept still works. A good example is the triple vacuum melt steel project. It is an expensive project for any one company to undertake, which makes it risky, but by doing it together the whole aerospace industry may see a benefit. Another example is the recent project to characterize the fatigue properties of AMS 6308 up to a “run out” limit of one billion cycles. With input from the various members as described in this newsletter, several new projects are about to be initiated.

Aerospace gear companies who are not part of the consortium yet are encouraged to contact Aaron Isaacson for additional information and join the group to get access to previous studies and influence the future direction.

Neil Anderson

Fellow, Gear Design

Pratt & Whitney

Research Project

As existing projects conclude, the Aerospace Bloc research consortium (sponsors: GE Aviation, Avio Aero, Bell Helicopter, Boeing, Carpenter Technology Corp., Honeywell, Pratt & Whitney-Canada, Pratt & Whitney-East Hartford, REM Surface Engineering, Rave Gears, Rolls Royce, Sikorsky and UTC Aerospace Systems) undertakes a process to establish and prioritize new research projects at the Gear Research Institute. Typically, this occurs once every few years. We are currently passing through such a period, which started late in 2017. Research topics of interest to each member of the bloc were solicited and a ballot listing their inputs was circulated to the group’s Steering Committee. The priority of each of the listed topics was also requested from the members and this input was tabulated to identify the “high” priority projects that could be considered for “pre-competitive, cooperative” execution. While there were a range of inputs, the top priority projects are easily identified, even from a fairly diverse group of participants. Presently, “Scuffing Evaluation and Loss of Lubrication Testing” was identified as the top priority followed by “Fully Reversed Bending Running Gear Fatigue Testing”.

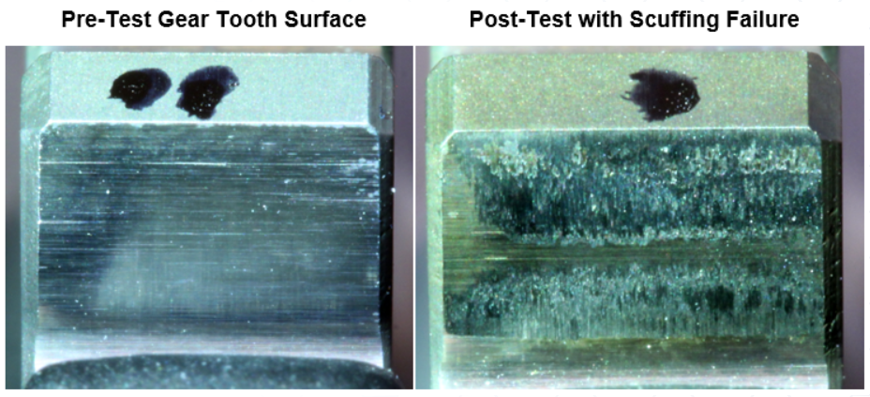

Figure 1: Post-test image of catastrophically failed test gears from loss of lube test.

In the first topic on Scuffing Evaluation and Loss of Lubrication Testing, it is planned to evaluate the scuffing resistance and loss of lube performance of test gears manufactured from a variety of aerospace gear steels. Alloys being considered are AISI 9310, Pyrowear 53, Pyrowear 675, Ferrium C-64 and M50-NiL. Various tooth surface treatments will also be evaluated. Surface treatments to be considered include isotropic superfinishing with the typical as-ground gear tooth surface serving as a base-line. Coatings were considered but were not included in this effort. While only one gear lubricant is planned for the current project, other lubricants will be considered if financial resources to conduct a larger program become available. Four Square, power re-circulating tests are planned for this effort utilizing ARL Penn State’s high speed (10,000 rpm) test rigs. These have been instrumented to measure effective friction at the tooth contact surfaces and have proven to be an invaluable tool for detecting the onset of scuffing and when catastrophic failure due to scuffing is imminent. The final material and surface treatment matrix will be determined through a second round of balloting from the members of the bloc. Funds have been allocated to evaluate up to five specific gear alloys and two specific surface treatments for scuffing resistance and loss of lubricant operability.

Fully reversed bending fatigue testing was also rated highly by the Bloc. Planet and idler gear applications are subject to fully reverse bending loads as they operate both as the driving and the driven gear. However, most fatigue tests to establish design allowable bending stresses, load the gear tooth in a single direction. This data is must be de-rated when designing idler or planet gears because applicable data is not available. Fully reversed bending stresses can be applied in a four square gear test rig through modification of the test boxes to accommodate an additional shaft to mount the test gear, which then operates as the driver and the driven as it engages with the input and output gears. This project will be considered in greater detail once the “priority one” project is fully established. Parallel processing of this project could be considered if additional financial resources were available (i.e. if more sponsors of the Aerospace Bloc were recruited). Additional research topics that received attention in the first round of balloting were contact and bending fatigue evaluation of other gear steels, contact fatigue evaluation of cavitation peened gears and evaluation of other surface treatments and super finishing methods. Currently ongoing Aerospace Bloc projects include Triple-Melt Gear Steels, Single Tooth Bending Fatigue of Optimized Cavitation Peened Gears, Very Long Cycle Fatigue of AMS 6308 and Mitigation of Micropitting.

Education and Training

In order to assist with replenishment of the gear industry’s aging work force, the Gear Research Institute has developed a hands on education program for students at both the undergraduate and graduate levels. The results of the program are entry level engineers that have been trained in the basics of gearing. This involves incorporating engineering undergraduate students, at the junior/senior level and graduate students in the Institute’s research laboratory while being paid by a grant from the sponsoring industrial entity. Summer internships have also been arranged at the sponsor’s facility, so that the student and the sponsor have an opportunity to assess each other with future employment in mind.

Typically, students get hands on experience by setting up and monitoring gear test equipment with additional training topics such as gear metrology, failure analysis, metallurgical characterization, vibration monitoring for failure detection, statistical analysis of test data and more.

This newsletter’s student profile is of Jena Griffin. Jena received her Bachelor of Science degree in Biological Engineering with an option in Agricultural Engineering and a minor in Off Road Equipment. Jena’s position was made possible through a grant from John Deere. She had been working in the GRI test lab supporting several projects since August of 2017. Jena graduated in May and has accepted a positon as a test engineer at New Holland Agriculture and Construction (CNH Industrial).

For more information about how you can support a student intern or sponsor a student project, please visit www.gearresearch.org or contact Aaron Isaacson at 814 865 5832 or This email address is being protected from spambots. You need JavaScript enabled to view it..

News

After 20 years of service to GRI, Sam Haines has retired from the Board of Trustees. Sam has served in many ways over the years, always giving his time to help wherever he could. Sam served multiple terms as GRI President and also acted as Treasurer for many years. He was presented with a replica Nittany Lion as a token of appreciation for his dedication to GRI at the fall meeting of the Board held at the Applied Research Lab at Penn State. Shown below are Jack Masseth, President (left) and Aaron Isaacson, Managing Director (right) presenting Sam with his Lion.

Chad Behrman was elected by GRI membership to fill the vacancy created by Sam’s retirement. Chad is a Technical Specialist at Rolls Royce Corporation in Indianapolis, IN. He has a lot of experience with transmission and structure design and is a Lean Six Sigma Blackbelt. Chad is also one of Rolls Royce’s representatives to the GRI Aerospace Bloc Steering Committee. We would like to welcome Chad to the Board and thank him for his continued commitment to serve GRI.

It is with great sadness that we announce the death of another friend of GRI. Dr. Gary Pozarnsky was founder and President of Applied Colloids, LLC. Dr. Pozarnsky had recently sponsored several projects at GRI to support the development of lubricants with low friction and anti-scuffing properties for both the automotive and aerospace markets. His personality and style were like no other sponsor we have worked with and he will certainly be missed. His obituary is given below

Obituary

Pozarnsky, Gary 54, Roseville, MN, formerly of Benedict, ND, passed away from natural causes Monday, December 11, 2017, at his home. Gary Allen Pozarnsky was born February 11, 1963, the son of Daniel and Bernice (Renfandt) Pozarnsky, in Minot, ND. He was raised in Benedict, ND and graduated from Max High School. Gary went on to the University of North Dakota, where he received his undergraduate degree in Chemical Engineering. He received his Doctorate in Chemical Engineering and the University of Minnesota and did his post-doctorate work at Clarkson University in New York. Gary had his own research company and had several patents working with the Department of Defense. He worked for 18 years seasonally with the Renaissance Festival of Shakopee and valued the friends with whom he worked there. He had recently been with his family for Thanksgiving in North Dakota. Surviving family includes: mother, Bernice Pozarnsky, Minot, ND. Funeral: Private family services will be held. Interment: Rosehill Memorial Park, Minot, ND. Guestbook: thompsonlarson.com

Employment Opportunities

We have added a “Job Postings” section to the GRI website for gear and drivetrain related positions. This service is offered free of charge to our Corporate members and sponsors. If you’re interested in having your company’s job openings listed, please contact Aaron Isaacson at This email address is being protected from spambots. You need JavaScript enabled to view it..

Please take a moment to check it out! http://gearresearch.org/job-postings.html.

The Gear Research Institute is a non profit corporation. It has contracted with the Applied Research Laboratory of The Pennsylvania State University to conduct its activities, as a sponsor within the Drivetrain Technology Center. The Gear Research Institute is equipped with extensive research capabilities. These include rolling contact fatigue (RCF) testers for low- and high-temperature roller testing, power circulating (PC) gear testers for parallel axis gears with a 4-inch center distance (testers can be modified to accommodate other center distances), single tooth fatigue (STF) testers for spur, helical and spiral bevel gears, and gear tooth impact tester. Extensive metallurgical characterization facilities are also available at Penn State in support of the Gear Research Institute. For further details on our testing capabilities please go to www.gearresearch.org or call Aaron Isaacson, Managing Director, at (814) 865-5832.