Oct 2015 Newsletter - Transmissions Vol 16, 2015

Vol. 16, 2015

Vol. 16, 2015

Transitions

Progress is a nice word but change is the motivator and change has its enemies: Robert Kennedy

Progress is a nice word but change is the motivator and change has its enemies: Robert Kennedy

Change happens all around us and there is change at the Gear Research Institute.

After his 3 year position as President of the Gear Research Institute, my longtime friend and mentor, Sam Haines, has passed the reins to me, these are big shoes to fill but I am up for the challenge.

Aaron Isaacson has also recently taken over the Managing Director and Chief Operating Officer position from Suren Rao, PhD who is enjoying his much deserved retirement.

Then there are some things that remain stable including Gleason Works which recently celebrated their 150th year anniversary and the AGMA which is celebrating their 100th year anniversary, these are truly amazing accomplishments.

There is nothing so stable as change, even in the “mature” gearing field. After accidentally ending up in the gearing world, (that is a story for another time) it is truly remarkable the amount of change I have seen in the 35 years I have been in this business. The jump from mechanical to fully CNC machines, integrated and accurate metrology systems, high speed cutting operations, advanced gear design and analysis software and environmentally friendly processes has been incredible. If I were to have guessed 35 years ago where we would be today, I know I would have been way off. One thing that has not changed is the need for leading edge gear research and testing and the development of our future gear leaders, this is where the Gear Research Institute can help.

So where will we be in the future? With the pace of change what it is, I cannot even imagine what it will be like in 35 years, much less 10 years. There will be challenges, opportunities and above all, change. We hope the Gear Research Institute can anticipate the future, fulfill your needs and exceed your expectations. We expect change and will be ready for it.

In closing, a quote from Steve Jobs: We’re just enthusiastic about what we do.

We know that applies to the Gear Research Institute, now and in the future.

Jack Masseth,

President GRI

Research Project

In all the fatigue testing, that is the forte of GRI, knowing when a certain consistent level of failure has occurred is vital. In many of the experimental efforts we undertake we compare the life to failure of one set of test specimens against the life to failure of another set of test specimens, in order to compare the durability of one versus the other. A consistent failure criterion is essential in this effort. This topic was briefly discussed in an earlier newsletter. More discussion and the theoretical basis of this topic are presented here.

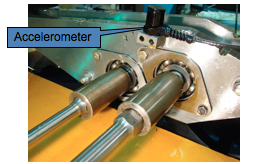

The traditional mode of detecting failure, in most gear and gear material testing has been to monitor the time domain vibration levels with an accelerometer mounted near the test mesh (figure 1). The failure criterion is typically an increase in RMS or peak vibration above a set threshold. This has been found to be very arbitrary as the level of vibration is dependent on several factors such as the speed, load, tooth geometry, the dynamic response of the test rig system and even background noise.

|

|

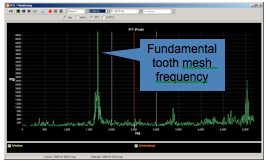

| Figure 1: Mounted Acceleromator | Figure 2: Acceleration Spectra |

In recent years, with the wider availability of hardware/software packages that are capable of Fast Fourier Transform (FFT) analysis, GRI has begun to monitor the acceleration levels at specific fundamental frequencies and their harmonics; with significantly improved results. Figure 2 shows a typical frequency spectrum (FFT) for a vibration signal from the 4-square gear test rig in figure 1. In this spectrum the fundamental tooth mesh frequency on the torque reversing gear pair is the large peak at about 1700 Hz. The peaks associated with the fundamental rotational frequency and its harmonics are on the left side of the large tooth mesh peak. The peaks to the right of the tooth mesh peak are further rotational harmonics; harmonics of the tooth mesh frequencies in the test box, harmonics of the tooth mesh frequencies in the torque reversing gear box and their accompanying side-bands. By monitoring energy levels at the specific relevant frequencies much more consistent and repeatable results are being obtained; whether it is a running gear bending fatigue tests or a surface durability test. While we are still fine-tuning this methodology for surface durability failures, we are confident that we are detecting the initiation of bending fatigue failure of running gear teeth in an extremely consistent and accurate manner and long before any other technique known can detect this failure.

The basis for monitoring the vibration level at certain fundamental frequencies and its harmonics is that the transmission error vibration excitation from meshing gear pairs contains information pertinent to the health of the gears. Further, in the case of bending fatigue, plastic tooth deformation constitutes the dominant source of gear-health changes prior to failure (1). This plastic deformation of the teeth leads to deviations of the loaded tooth working surface from a perfect equi-spaced position. If the meshing gears are operating at a constant speed and load, the deviations of the loaded tooth-working-surface manifest themselves in the transmission error of the meshing gear pair and in the generated vibration spectra.

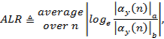

In the research at ARL/Penn State, a metric defined as the Average-Log-Ratio (ALR) to quantify the health of the gear has been developed (2). The ALR is defined by the equation below and a value of the ALR significantly larger than zero and increasing in running time is an indication of damage on one or more teeth of the gear.

The transducer-response Fourier series coefficients αy(n) are related to the transmission-error Fourier series coefficients and complex-frequency-response function; more details on the above equation are provided in reference 2. This metric was evaluated for a pair of running spiral bevel gears. Figure 3 shows the progression of the value of the ALR metric for the meshing gears. Increases in the ALR indicate the onset of damage, i.e. plastic deformation or an increase in transmission error.

In this figure the value of the ALR, computed with statistical averaging, remained almost constant until approximately 2 hours and 30 minutes running time, but then began to increase monotonically till about 4 hours of operation when the gear pair loading was reduced. After further running the ALR metric again increases as damage to the gear tooth progresses. This methodology developed could be an approach to gear health monitoring in gear boxes as the diagnostics and prognostics of mechanical machinery becomes an essential requirement of such systems.

References

- Mark, W. D. et al. Assessing the role of plastic deformation in gear-health monitoring by precision measurement of failed gears, Mechanical Systems and Signal Processing 21, 2007, pp. 177-192.

- Hines, J. A. and Mark, W. D., Bending fatigue damage detection on notched tooth, spiral bevel gear using the average-log-ratio, ALR Algorithm, Mechanical Systems and Signal Processing, 43, 2014, pp. 44-56.

Education and Training

In order to assist the gear industry augment its aging work force, the Gear Research Institute has developed two initiatives to train more gear knowledgeable engineers at the undergraduate and graduate levels. This involves incorporating engineering undergraduate students, at the junior/senior level and graduate students in the Institute’s research laboratory while being paid by a grant from the sponsoring industrial entity. Summer internships have also been arranged at the sponsor’s facility are also a part of the deal, so that the student and the sponsor have an opportunity to assess each other with future employment in mind.

We had our first graduate of this program in the spring of 2013, who then joined John Deere at their Coffeyville, KS facility. We had a second student selected by John Deere, Byron Stuart, who graduated last spring and joined John Deere at their Waterloo, Iowa facility in August 2014. Our third student supported by John Deere, William Jaundalderis, a senior in Mechanical Engineering, will graduate this year but plans to join the United States Air Force upon graduation. We now have a fourth student, David Reed supported by John Deere working with us and prospectively joining John Deere upon graduation in 2016.

Typically, students get hands on experience by setting up and monitoring gear test equipment with additional training topics such as gear metrology, failure analysis, metallurgical characterization, vibration monitoring for failure detection, statistical analysis of test data and more.

For more information about how you can support a student intern please log in to www.gearresearch.org or contact Aaron Isaacson at 814 865 5832 or This email address is being protected from spambots. You need JavaScript enabled to view it..

The Gear Research Institute is a non profit corporation. It has contracted with the Applied Research Laboratory of The Pennsylvania State University to conduct its activities, as a sponsor within the Drivetrain Technology Center. The Gear Research Institute is equipped with extensive research capabilities. These include rolling contact fatigue (RCF) testers for low- and high-temperature roller testing, power circulating (PC) gear testers for parallel axis gears with a 4-inch center distance (testers can be modified to accommodate other center distances), single tooth fatigue (STF) testers for spur, helical and spiral bevel gears, and gear tooth impact tester. Extensive metallurgical characterization facilities are also available at Penn State in support of the Gear Research Institute. For further details on our testing capabilities please go to www.gearresearch.org or call Aaron Isaacson, Managing Director, at (814) 865-5832..